Energy Efficiency Existing Ship Index (EEXI) & Computational Fluid Dynamics (CFD)

Overview

EEXI (Energy Efficiency Existing Ship Index) was adopted by IMO as a short-term technical measure to reduce GHG emissions. This was adopted via amendments made to MARPOL Annex VI during the 76th session of MEPC, held in June of 2021. It is in line with IMO’s current GHG reduction goal to peak GHG emissions from international shipping as soon as possible and to reduce the total annual GHG emissions by at least 50% by 2050 compared to 2008 whilst pursuing efforts towards phasing them out.

EEXI requires all ships of 400GT and above to have an attained EEXI number calculated. This attained EEXI number should be less than or equal to the required EEXI number which varies according to ship types and their size category.

EEXI takes into consideration all the design parameters of the ship relevant to with its GHG emission capabilities, its purpose and its size. It does not consider the operational parameters of the ship.

Entry into force

As per IMO: "The amendments to MARPOL Annex VI (adopted in a consolidated revised Annex VI) are expected to enter into force on 1 November 2022, with the requirements for EEXI and CII certification coming into effect from 1 January 2023."

Impact:

All vessels subject to this regulation need to demostrate their EEXI compliance before 1st of January 2023 or their next survey whichever is first, so that their International Energy Efficiency Certificate (IEEC) can be issued. This is a very short timeline with repercussions of non-compliance.

If the vessel has a higher attained EEXI than the required EEXI, then the vessel will have to implement an overridable Engine power limitation or Shaft power limitation (EPL/ShaPOLi). This is a form of pseudo-de-rating of the engine to a reduced MCR, thereby limiting the ship to lower normal operating speeds. This EPL/ShaPOLi can be disengaged in case of an emergency such as extreme weather.

What can Verifavia Shipping do for you?

With our extensive experience and expertise in environmental compliance, we offer you end-to-end support and services on the road to EEXI compliance, Including the EEXI technical file preparation and CFD analysis of your vessel to acquire the Vref or to determine the impact of Energy Savings Devices (ESD) on EEXI.

Our experienced team of marine engineers and naval architects work to make the entire process seamless and ensure the compliance of your ships in the most efficient and economical manner.

From initial EEXI calculation and Technical file preparation to approval, we will be there every step of the way, providing you support and expertise.

Computational Fluid Dynamics (CFD) and EEXI

Verifavia Shipping can also conduct CFD (Computational Fluid Dynamics) simulations to support EEXI compliance by improving your ship’s EEXI value and bring down the overall impact of EEXI on your ship’s performance.

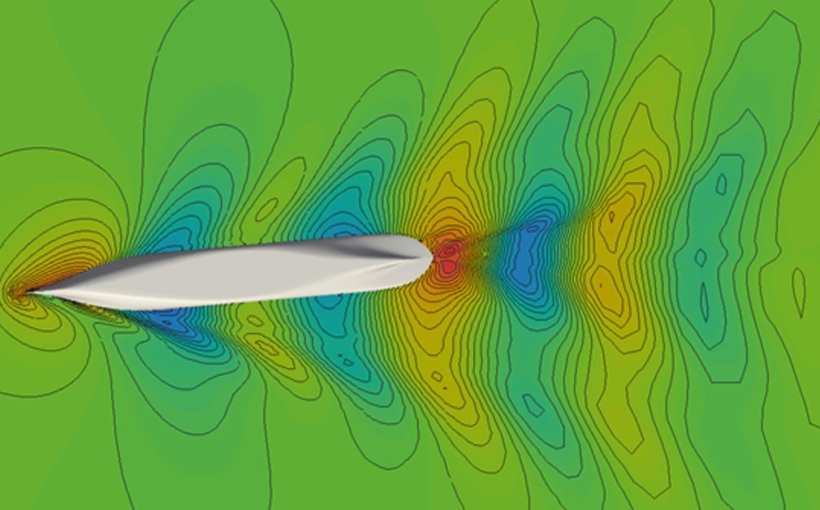

CFD is a branch of Fluid dynamics that solves flow related problems using high powered computers to run 3D models. It is generally based on the Navier-Strokes equation and the Reynolds- Averaged Navier Strokes (RANS) equation for turbulent flows.

CFD has widespread application in aerospace, oil and gas, automobile, marine sectors and many more. For ships, it is generally conducted during their concept and initial design stages to generate the speed – power curves. It is a very powerful and relatively economical tool when compared to conventional towing tanks.

(Picture for reference only. Source: https://blog.engys.com/open-source-cfd-solutions-for-the-marine-industry/)

One of the major parameters affecting Attained EEXI is the reference speed (vref) of the vessel. This is the speed of the vessel for 75% MCR at EEXI draft condition and is obtained from the sea trials report of the vessel. Generally, the sea trial is conducted at the ballast draft condition for bulk carriers and container ships while their EEXI draft requirement is the summer load line and 70% deadweight condition respectively. Under these conditions, where the required speed power curve is unavailable, the reference speed is calculated as per the formula given in the EEXI calculation guidelines (MEPC 333(76)), this formula is based on statistical data of ships of several types and has a 5% speed reduction margin. This generally leads to a higher EEXI number compared to EEXI number calculated using the actual reference speed.

The alternative to this formula is to estimate the vref using numerical calculations such as CFD etc. and to calibrate the estimates with the speed trial reports. This will result in a more accurate and possibly a favorable EEXI number.

Furthermore, CFD simulations can be used to predict ship specific speed-power curves for ESD (Energy Saving Devices) modification proposals. Energy saving devices that change the powering characteristics of a ship such as propeller ducts and modified bulbous bows need ship specific sea trials, towing tank tests or CFD reports that can support the impact of ESDs on the ship speed in EEXI calculations.

Please contact us for further information and collaboration

Regulations & Guidelines:

Resolution MEPC.333(76) 2021 Guidelines on Calculation of EEXI

Resolution MEPC.334(76) 2021 Guidelines on Survey and Certification of EEXI

Resolution MEPC.335(76) 2021 Guidelines on Shaft & Engine Power Limitation

MEPC.308(73) - 2018 Guidelines on method for EEDI calculations for new ships

MEPC.328(76) - 2021 Revised MARPOL Annex VI

Resolution MEPC.333(76) 2021 Guidelines on Calculation of EEXI

Resolution MEPC.334(76) 2021 Guidelines on Survey and Certification of EEXI

Resolution MEPC.335(76) 2021 Guidelines on Shaft & Engine Power Limitation

MEPC.308(73) - 2018 Guidelines on method for EEDI calculations for new ships

MEPC.328(76) - 2021 Revised MARPOL Annex VI