Which methods can be used to calculate fuel consumption?

The company shall define in the monitoring plan which monitoring methodology is used to calculate fuel consumption for each ship type under its responsibility and ensure that once it has been chosen, is consistently applied.

In selecting a monitoring methodology, the improvements from greater accuracy shall be balanced against the additional costs.

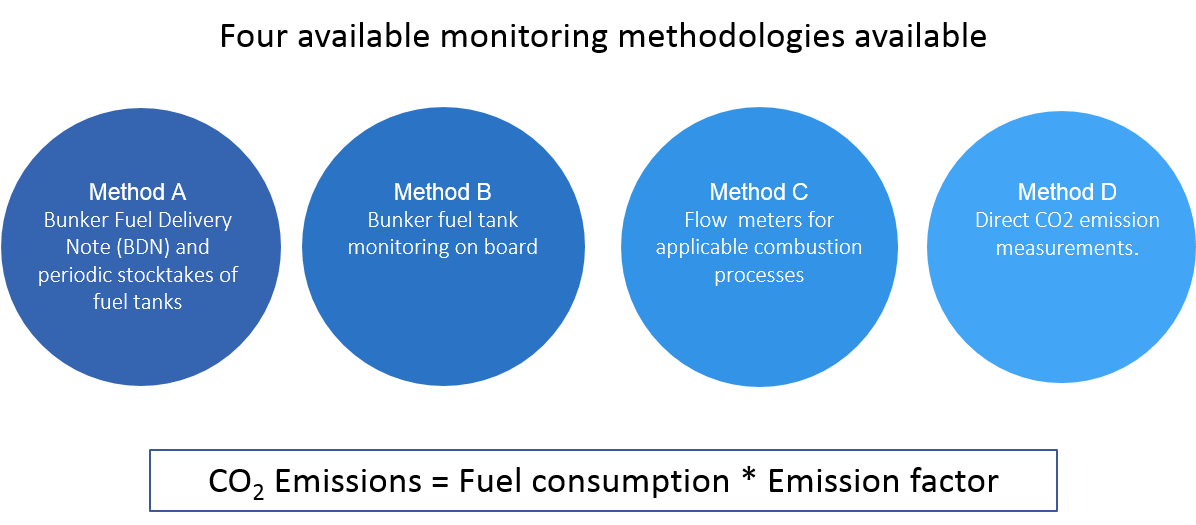

Actual fuel consumption for each voyage shall be used and be calculated using one of the following methods:

- A: Bunker Fuel Delivery Note (BDN) and periodic stocktakes of fuel tanks

- B: Bunker fuel tank monitoring on board

- C: Flow meters for applicable combustion processes

- D: Direct emissions measurements

A. Calculation of carbon emissions

For the purposes of calculating CO2 emissions companies shall apply the following formula:

Fuel consumption × emission factor

Fuel consumption shall include fuel consumed by main engines, auxiliary engines, gas turbines, boilers and inert gas generators.

Fuel consumption within ports at berth shall be calculated separately.

In principle, default values for emission factors of fuels shall be used unless the company decides to use data on fuel quality set out in the Bunker Fuel Delivery Notes (BDN) and used for demonstrating compliance with applicable regulations of sulphur emissions.

Those default values for emission factors shall be based on the latest available values of the Intergovernmental Panel for Climate Change (IPCC). Those values can be derived from Annex VI to Commission Regulation (EU) No 601/2012 (1).

Appropriate emission factors shall be applied in respect of biofuels and alternative non-fossil fuels.

B. Methods for determining carbon emissions

The company shall define in the monitoring plan which monitoring method is to be used to calculate fuel consumption for each ship under its responsibility and ensure that once the method has been chosen, it is consistently applied.

Actual fuel consumption for each voyage shall be used and be calculated using one of the following methods:

- (A) Bunker Fuel Delivery Note (BDN) and periodic stocktakes of fuel tanks;

- (B) Bunker fuel tank monitoring on board;

- (C) Flow meters for applicable combustion processes;

- (D) Direct CO2 emissions measurements.

Method A: BDN and periodic stocktakes of fuel tanks

This method is based on the quantity and type of fuel as defined on the BDN combined with periodic stocktakes of fuel tanks based on tank readings. The fuel at the beginning of the period, plus deliveries, minus fuel available at the end of the period and de-bunkered fuel between the beginning of the period and the end of the period together constitute the fuel consumed over the period.

The period means the time between two port calls or time within a port. For the fuel used during a period, the fuel type and the sulphur content need to be specified.

This method shall not be used when BDN are not available on board ships, especially when cargo is used as a fuel, for example, liquefied natural gas (LNG) boil-off.

Under existing MARPOL Annex VI regulations, the BDN is mandatory, is to be retained on board for three years after the delivery of the bunker fuel and is to be readily available. The periodic stocktake of fuel tanks on-board is based on fuel tank readings. It uses tank tables relevant to each fuel tank to determine the volume at the time of the fuel tank reading. The uncertainty associated with the BDN shall be specified in the monitoring plan. Fuel tank readings shall be carried out by appropriate methods such as automated systems, soundings and dip tapes. The method for tank sounding and uncertainty associated shall be specified in the monitoring plan.

Where the amount of fuel uplift or the amount of fuel remaining in the tanks is determined in units of volume, expressed in litres, the company shall convert that amount from volume to mass by using actual density values. The company shall determine the actual density by using one of the following:

- on-board measurement systems

- the density measured by the fuel supplier at fuel uplift and recorded on the fuel invoice or BDN

- the density measured in a test analysis conducted in an accredited fuel test laboratory, where available

Method B: Bunker fuel tank monitoring on-board

This method is based on fuel tank readings for all fuel tanks on-board. The tank readings shall occur daily when the ship is at sea and each time the ship is bunkering or de-bunkering.

The cumulative variations of the fuel tank level between two readings constitute the fuel consumed over the period.

The period means the time between two port calls or time within a port. For the fuel used during a period, the fuel type and the sulphur content need to be specified.

Fuel tank readings shall be carried out by appropriate methods such as automated systems, soundings and dip tapes. The method for tank sounding and uncertainty associated shall be specified in the monitoring plan.

Where the amount of fuel uplift or the amount of fuel remaining in the tanks is determined in units of volume, expressed in litres, the company shall convert that amount from volume to mass by using actual density values. The company shall determine the actual density by using one of the following:

- on-board measurement systems

- the density measured by the fuel supplier at fuel uplift and recorded on the fuel invoice or BDN

- the density measured in a test analysis conducted in an accredited fuel test laboratory, where available

Method C: Flow meters for applicable combustion processes

This method is based on measured fuel flows on-board. The data from all flow meters linked to relevant CO2 emission sources shall be combined to determine all fuel consumption for a specific period.

The period means the time between two port calls or time within a port. For the fuel used during a period, the fuel type and the sulphur content need to be monitored.

The calibration methods applied and the uncertainty associated with flow meters used shall be specified in the monitoring plan.

Where the amount of fuel consumed is determined in units of volume, expressed in litres, the company shall convert that amount from volume to mass by using actual density values. The company shall determine the actual density by using one of the following:

- on-board measurement systems

- the density measured by the fuel supplier at fuel uplift and recorded on the fuel invoice or BDN

Method D: Direct CO2 emissions measurement

The direct CO2 emissions measurements may be used for voyages and for CO2 emissions occurring in ports located in a Member State's jurisdiction. CO2 emitted shall include CO2 emitted by main engines, auxiliary engines, gas turbines, boilers and inert gas generators. For ships for which reporting is based on this method, the fuel consumption shall be calculated using the measured CO2 emissions and the applicable emission factor of the relevant fuels.

This method is based on the determination of CO2 emission flows in exhaust gas stacks (funnels) by multiplying the CO2 concentration of the exhaust gas with the exhaust gas flow.

The calibration methods applied and the uncertainty associated with the devices used shall be specified in the monitoring plan.

Source: Regulation 2015/757 Annex I

Back to all F.A.Q.